Wonderful Info About What Is Splice In Construction

What Exactly Is a Splice in Construction? Let's Break It Down

1. Understanding the Basics of Splices

Alright, imagine you're building something big, like a skyscraper or a long bridge. Now, the individual pieces of material you're using — steel beams, wooden planks, even concrete sections — probably aren't long enough to span the entire distance in one go. That's where the splice comes in! Simply put, a splice is a method of joining two or more structural members end-to-end. Its like giving those shorter pieces the ability to act as one continuous, longer piece.

Think of it like connecting train tracks. You can't just lay down short sections and hope for the best, right? You need a way to join them securely and seamlessly so the train can travel smoothly. A splice in construction does the same thing for structural elements. It ensures that the load is transferred effectively from one member to the next, maintaining the integrity of the entire structure.

Now, why not just use longer materials in the first place? Well, there are several reasons. Sometimes its simply not feasible to manufacture or transport extremely long pieces. Other times, its more economical to use standard-sized pieces and splice them together. And in some cases, splices allow for easier installation or adjustments during the construction process. So, the splice is actually a clever and practical solution to a common construction challenge.

But here's a thing to keep in mind: a poorly executed splice is like a weak link in a chain. If it's not done correctly, it can compromise the strength and stability of the entire structure. That's why proper design, careful execution, and thorough inspection of splices are absolutely crucial in construction projects. It's definitely not something you want to cut corners on!

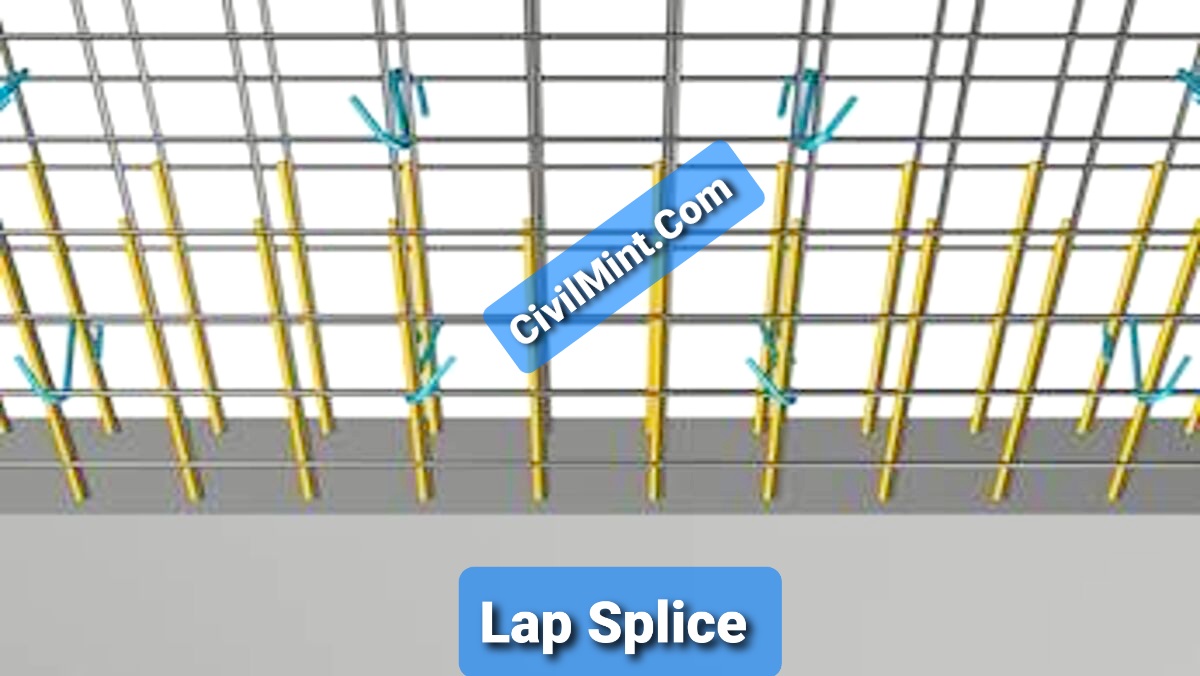

Lap Splice Reinforcement

Why Are Splices So Important? More Than Just Joining Two Things

2. The Vital Role of Splices in Structural Integrity

Beyond simply connecting two pieces, splices play a critical role in distributing loads throughout the structure. A well-designed splice ensures that the forces acting on one member are efficiently transferred to the adjoining member, preventing stress concentrations and potential failure points. Its all about sharing the burden, you see?

Think of a bridge, for example. The weight of the vehicles and the bridge itself is transferred through the deck, down to the supporting beams, and then through the splices to the supporting columns. If the splices are weak or poorly designed, they could buckle under the pressure, leading to catastrophic consequences. So, they're pretty darn important!

Furthermore, splices can also help to accommodate for variations in material properties or construction tolerances. Sometimes, the actual dimensions of the structural members might slightly differ from the design specifications. Splices can be designed to compensate for these discrepancies, ensuring a tight and secure fit. It is the construction equivalent of a tailor ensuring the suit fits perfectly.

And let's not forget about durability. Splices need to be able to withstand the same environmental conditions as the rest of the structure, including exposure to moisture, temperature changes, and corrosive substances. That's why the choice of materials and the method of splicing are so important for ensuring the long-term performance of the structure. Choosing the right materials will help guarantee that your structure stands the test of time.

Advantages And Types Of Mechanical Splices For Concrete Rebar

Different Types of Splices

3. Exploring the Variety of Splicing Techniques

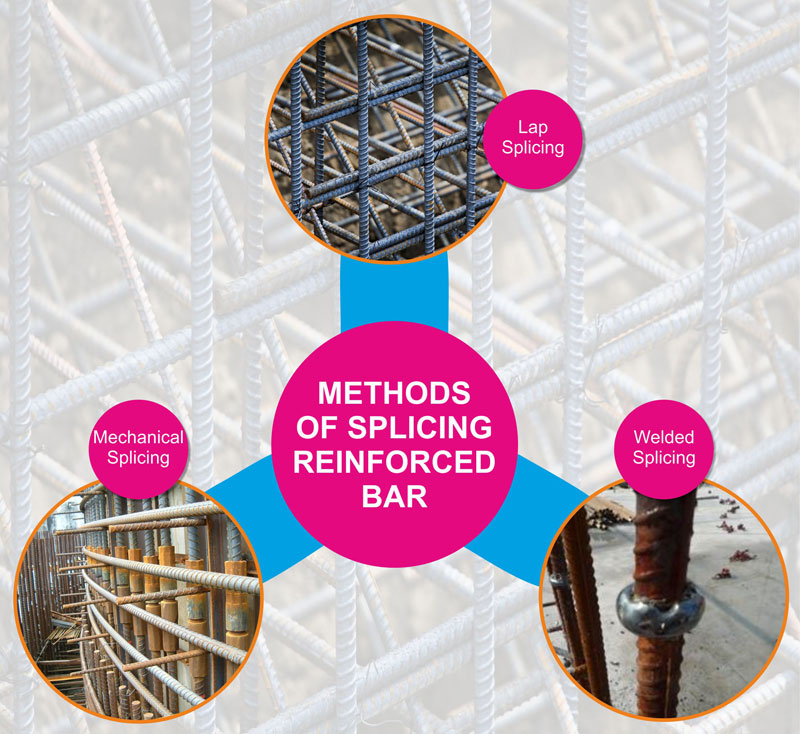

Alright, so you know what a splice is and why it's important. Now let's talk about the different types of splices. There are several methods used in construction, each with its own advantages and disadvantages, depending on the materials being joined, the loads being transferred, and the site conditions. Its like choosing the right tool for the right job.

One common type is the bolted splice, where two members are joined together using high-strength bolts. This method is relatively simple and cost-effective, making it a popular choice for steel structures. However, bolted splices can be susceptible to loosening over time, so regular inspection and maintenance are essential. A loose bolt is never good.

Welded splices, on the other hand, involve fusing the two members together using welding techniques. This creates a strong and permanent connection, but requires skilled welders and careful quality control to ensure the integrity of the weld. Welding can be more expensive than bolting, but is often preferred for critical applications where maximum strength is required. Welding is a job best left to professionals.

There are also mechanical splices, which use special connectors or fittings to join the members together. These can be particularly useful for joining concrete reinforcing bars (rebar), as they eliminate the need for overlapping the bars, which can be space-consuming. Mechanical splices offer a quick and reliable connection, making them a time-saving option on site. Dont forget epoxy splices, which are often used for concrete structures and utilize adhesive materials to provide the necessary bond. The type of splice utilized will heavily depend on material, structure and budget!

Splices in Different Materials

4. Adapting Splicing Techniques to Various Construction Materials

The specific method used to create a splice often depends on the type of material being used. Let's quickly look at how splices are handled in steel, concrete, and wood construction.

For steel structures, bolting and welding are the most common methods. Bolted splices are frequently used for connecting steel beams and columns, offering a balance between cost and strength. Welded splices, on the other hand, are often preferred for more demanding applications, such as bridges and high-rise buildings, where maximum strength and durability are crucial. Both have their place, it just depends on the situation!

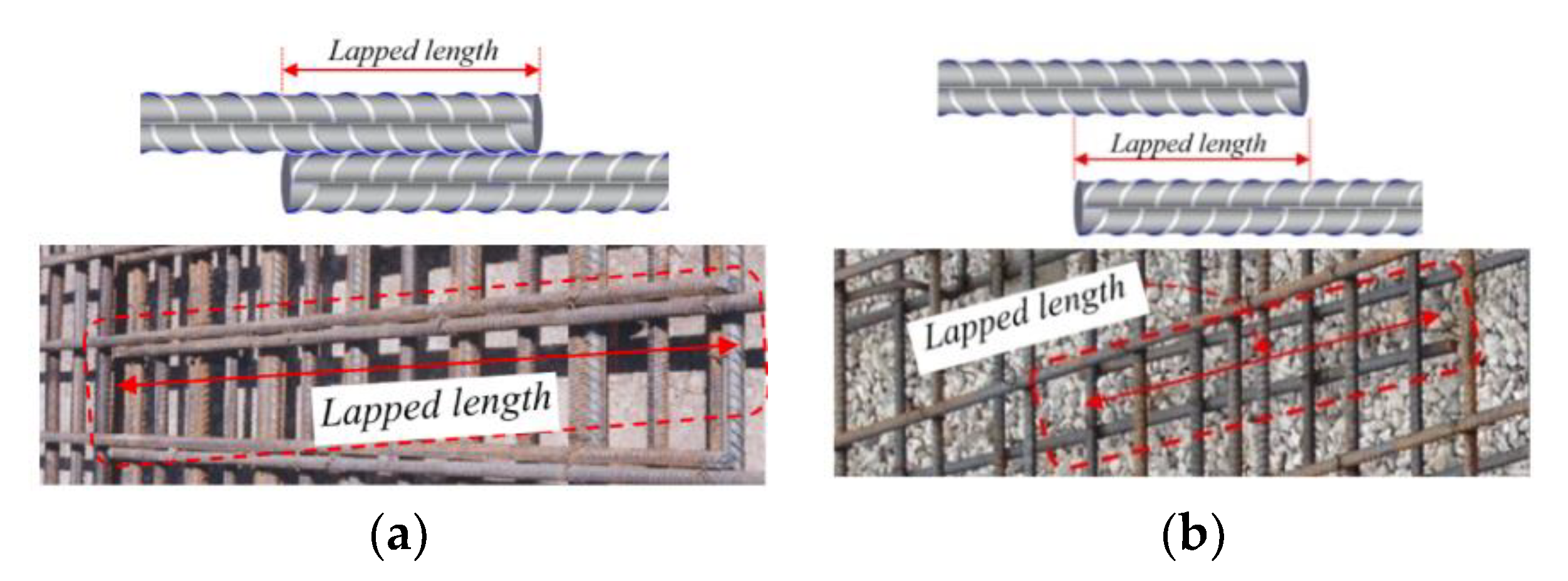

In concrete construction, splices are primarily used for joining reinforcing bars (rebar). Mechanical splices and lap splices (where the bars overlap) are the most common techniques. Mechanical splices provide a strong and reliable connection, while lap splices are simpler and more economical, but require careful detailing to ensure adequate bond between the concrete and the rebar. Bond is everything in concrete!

When it comes to wood construction, splices are typically achieved using mechanical fasteners, such as bolts, screws, and nails, or with adhesives. Wood splices can be tricky, as wood is a natural material with varying grain patterns and moisture content. Therefore, proper design and detailing are essential to ensure that the splice is strong and durable. Wood, while beautiful, can be unpredictable. The type of wood has to be carefully considered, as well as environmental factors.

Ensuring Splice Quality

5. Maintaining the Integrity of Splices Over Time

Creating a good splice is only half the battle. Maintaining its integrity over time is just as important. Regular inspection and maintenance are essential to identify any potential problems and ensure that the splice continues to perform as intended throughout the lifespan of the structure. Its like giving your building a regular check-up.

For bolted splices, the primary concern is bolt loosening. Regular inspections should be conducted to check the torque of the bolts and re-tighten them as necessary. In corrosive environments, the bolts may also need to be treated with protective coatings to prevent rust and corrosion. Keep those bolts tight and shiny!

Welded splices, while generally more durable, should also be inspected for any signs of cracking or corrosion. Non-destructive testing methods, such as ultrasonic testing or radiographic testing, can be used to detect hidden defects in the weld. Any damaged or corroded welds should be repaired or replaced promptly. Nothing lasts forever, so stay vigilant!

For splices in concrete structures, the main concern is corrosion of the reinforcing bars. This can be caused by exposure to moisture, chlorides, or other corrosive substances. Regular inspections should be conducted to check for signs of cracking, spalling, or staining of the concrete, which could indicate corrosion of the rebar. Preventative measures, such as applying protective coatings or using corrosion-resistant rebar, can also help to extend the lifespan of the splice. A little protection goes a long way.

Types Of Rebar Splices At Frieda Krull Blog

FAQ

6. Frequently Asked Questions

Q: What happens if a splice fails?A: A splice failure can have serious consequences, potentially leading to structural instability or even collapse. The severity of the failure depends on the location of the splice, the magnitude of the loads being transferred, and the overall redundancy of the structure. Any sign of a problem with the splice should be immediately addressed.

Q: Can splices be used in all types of construction?A: Yes, splices can be used in various types of construction, including steel, concrete, and wood. However, the specific method used to create the splice will vary depending on the material and the application. Its about using the right approach for the right job.

Q: Are splices always necessary?A: No, splices are not always necessary. If it's possible to use a single, continuous piece of material, that's usually the preferred option. However, in many cases, splices are required due to limitations in material size, transportation constraints, or construction considerations. Theyre a solution to a problem, not a problem themselves!

Q: How are splices designed?A: Splices are designed by structural engineers who consider factors such as the loads being transferred, the material properties, and the environmental conditions. The design process typically involves calculations to determine the required size and strength of the splice components, as well as the spacing and arrangement of fasteners or welds. Its not just slapping two things together; theres science involved!