Ideal Info About What Are The Limitations Of Torque

What Is Frictional Torque At Arthur Dwyer Blog

Understanding Torque

1. What is Torque, Really?

Torque. It's a word you often hear thrown around when talking about cars, engines, and anything involving rotational force. Simply put, it's the measure of how much "twisting force" is acting on an object. Think of it like this: a longer wrench gives you more leverage to loosen a stubborn bolt, right? That leverage is torque in action. It's what gets things moving and keeps them spinning.

However, focusing solely on torque figures can be misleading. It's easy to get caught up in the "more torque is always better" mentality, but the truth is much more nuanced. Like any tool, torque has its limitations, and understanding them is crucial for making informed decisions, whether you're choosing a vehicle or designing a machine.

We often associate high torque with powerful vehicles capable of towing heavy loads or accelerating quickly. While that's generally true, it's not the whole story. The way torque is delivered, the speed at which it's available, and the overall application all play significant roles in determining the usefulness of torque.

Consider a tractor, for example. It needs massive amounts of torque at low speeds to pull heavy equipment through fields. A sports car, on the other hand, prioritizes torque at higher engine speeds for thrilling acceleration. Both have high torque, but they use it in drastically different ways. Let's dive into some of the specific limitations that apply to torque.

The RPM Relationship

2. Torque vs. Horsepower

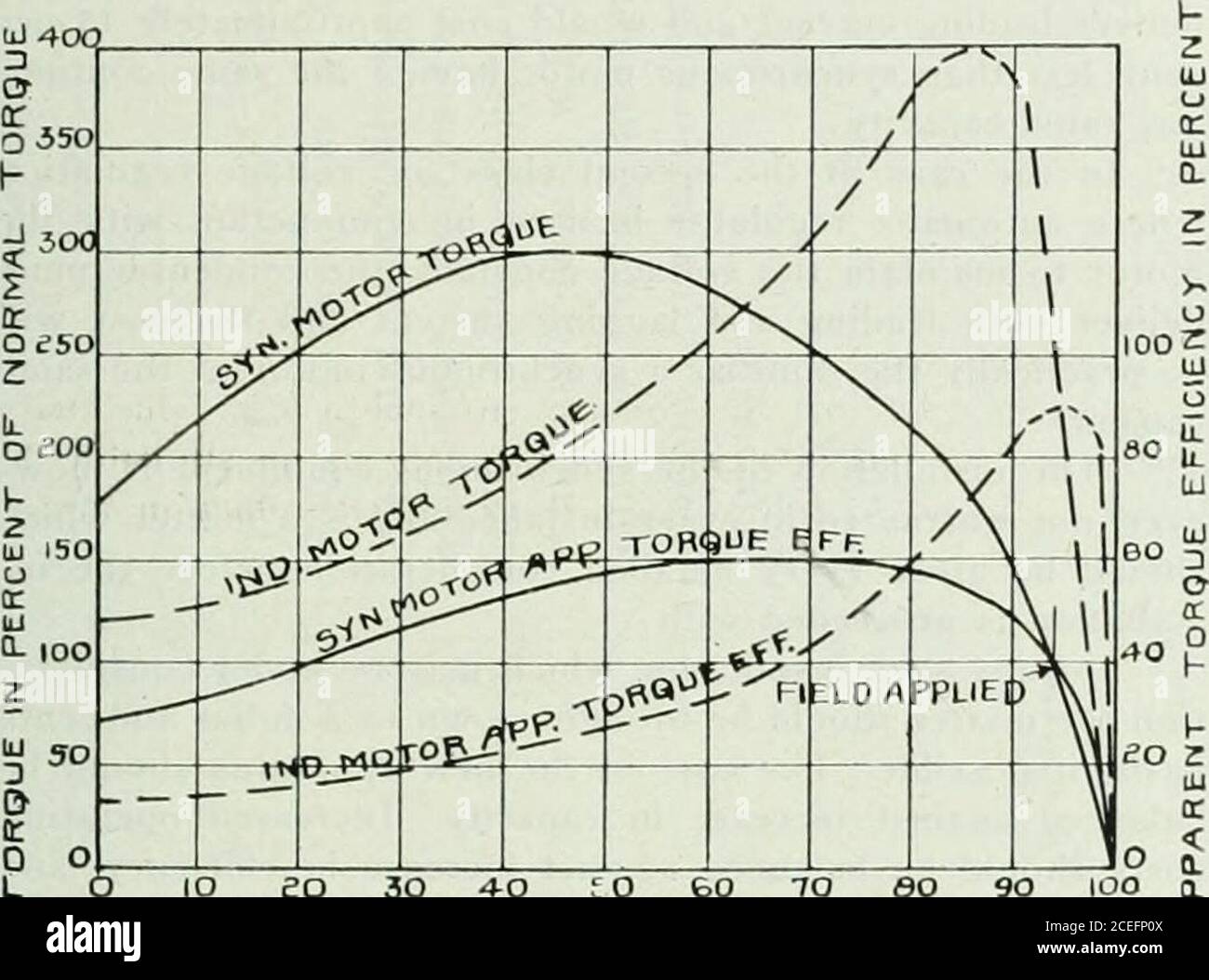

Torque doesn't exist in a vacuum. It's inextricably linked to RPM (revolutions per minute), and this relationship defines horsepower. Horsepower, the rate at which work is done, is directly proportional to torque and RPM. This means that while you might have a huge amount of torque at low RPM, if that torque drops off quickly as RPM increases, you won't have much horsepower at higher speeds. Think of it as short burst of strength versus endurance.

Imagine two engines: Engine A produces 500 lb-ft of torque at 2000 RPM, while Engine B produces 400 lb-ft of torque at 5000 RPM. Engine B might feel less powerful at low speeds, but it will likely have more horsepower and better performance at higher speeds due to its ability to maintain torque further up the RPM range. This is why sports cars often have relatively lower peak torque figures than trucks, but still feel incredibly fast.

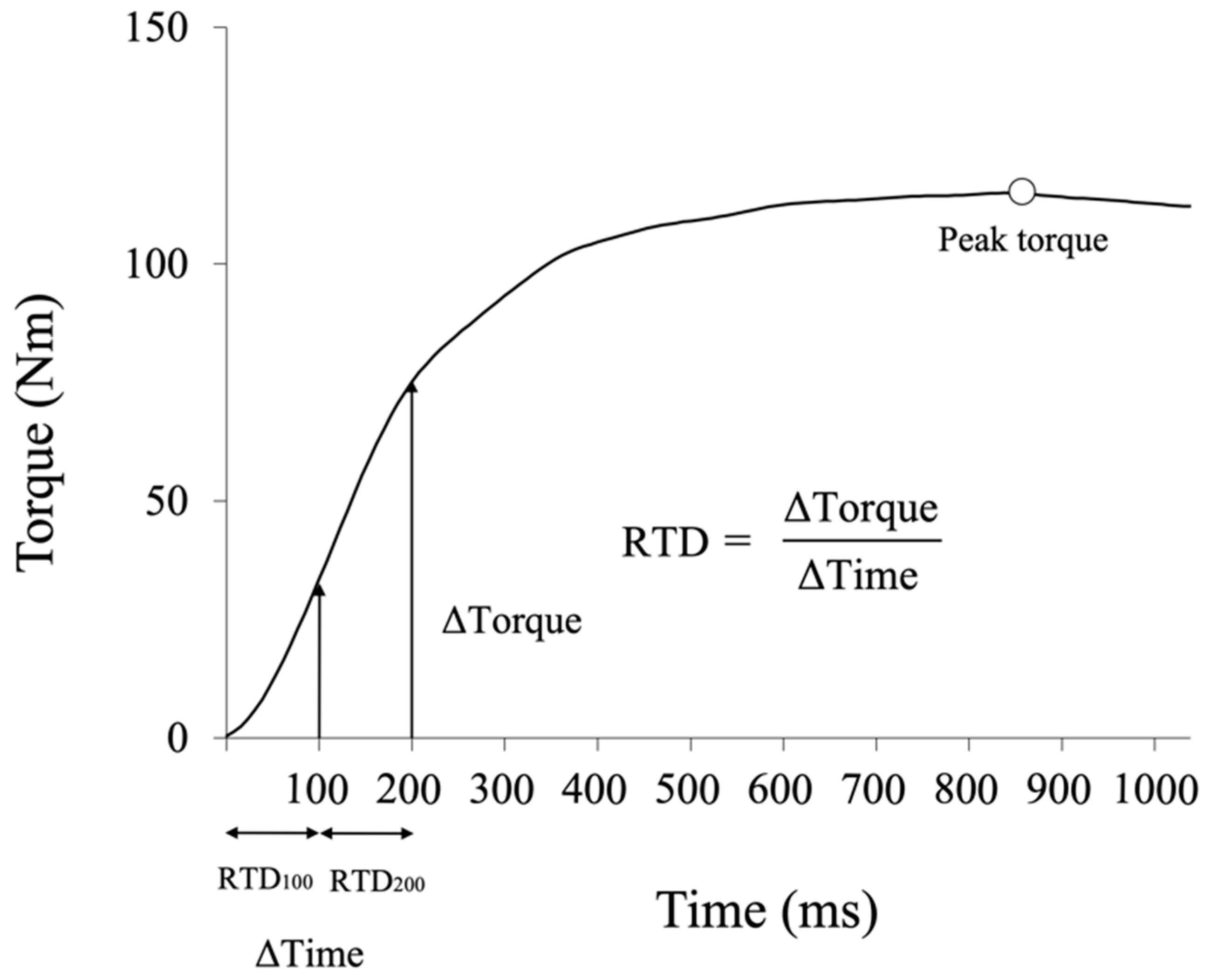

Therefore, it's crucial to consider the entire torque curve — how torque changes across the RPM range — rather than just the peak torque number. A broad, flat torque curve, where torque is readily available across a wide range of RPMs, is often more desirable than a narrow peak, especially for everyday driving. A narrow peak mean all the fun is in one small spot of the engine, makes things difficult and less fun.

The best engine combines high peak torque with a broad powerband. That's how you get the best performance. But this is expensive to do, so compromises are made. It's a bit of an art as much as it is engineering.

Concept Of Torque Sign Conventions Rotational Motion YouTube

Material Strength

3. When Too Much Torque Leads to Breakage

Every material has a limit to how much stress it can withstand before it deforms or breaks. When you apply torque to an object, you're essentially subjecting it to twisting stress. If the torque exceeds the material's torsional strength, you're going to have a problem. This is especially true for rotating components like axles, shafts, and gears.

Consider an axle in a high-powered truck. If you suddenly apply a massive amount of torque, especially under harsh conditions like off-roading, the axle might twist and snap. That's why engineers carefully design these components to withstand the expected torque levels, often with a safety factor built in. The safety factor accounts for unexpected overloads and material imperfections. This is why sometimes aftermarket parts built for more torque are built with better materials.

Material selection is also paramount. High-strength alloys like chrome-moly steel are often used in applications where high torque and durability are required. These materials can handle significantly more stress than conventional steel, but they also come at a higher cost. It is a compromise, but it is neccessary.

So, while it might be tempting to add a performance upgrade that significantly increases torque, it's crucial to ensure that the drivetrain components can handle the added stress. Otherwise, you're just setting yourself up for expensive repairs. It's all part of the big engineering equation.

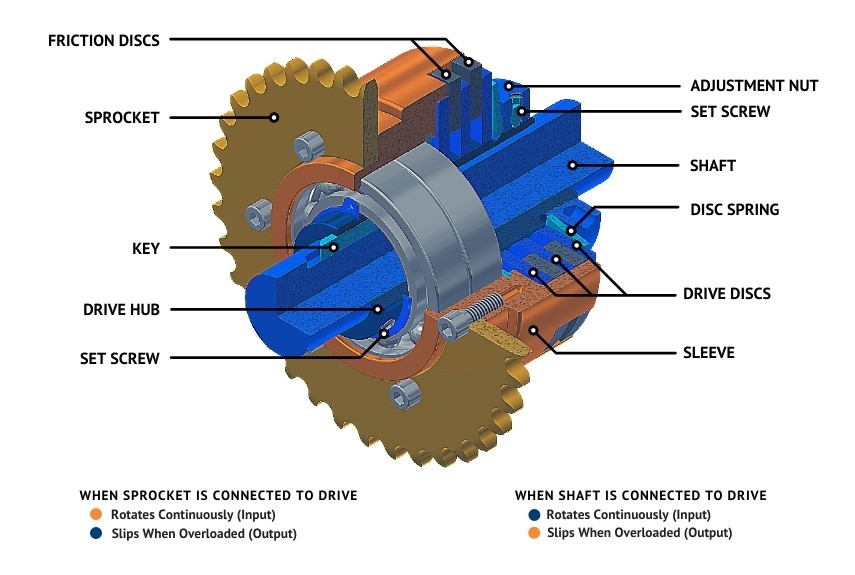

What Is A Torque Limiter? TSUBAKI OF CANADA LIMITED

Gearing and Mechanical Advantage

4. The Trade-Off

Gears are ingenious devices that allow us to multiply torque, but there's a catch: you lose speed in the process. Think of a bicycle. When you're in a low gear, you can easily climb hills (high torque), but you're not going very fast. When you shift to a higher gear, you can go much faster, but it takes more effort (lower torque). This is the fundamental principle of gearing.

The same principle applies to vehicles. Transmissions use different gear ratios to optimize torque for different situations. Low gears provide high torque for acceleration and climbing, while high gears provide lower torque for cruising at highway speeds. The gear ratio determines the amount of torque multiplication, but it also inversely affects the output speed.

Limited space and mechanical complexity mean there's a limit to how much gear reduction you can practically achieve. You can't just keep adding gears to infinitely increase torque because eventually, the system becomes inefficient and unmanageable. There is a balance that must be struck, always. It is usually a hard decision to figure out which is best.

Also, the size and strength of gears also impact the amount of torque that can be transmitted reliably. Small, weak gears will break under high loads. The engineers account for this, to make sure everything runs smooth and to its best ability.

IJERPH Free FullText Rate Of Torque Development In The Quadriceps

Traction

5. Putting the Power to the Ground

All the torque in the world is useless if you can't effectively transfer it to the ground. That's where traction comes in. Traction is the force that allows your tires to grip the road surface and propel you forward. Without sufficient traction, your wheels will simply spin, and you won't go anywhere, no matter how much torque you have.

Several factors affect traction, including tire type, road surface conditions (wet, dry, icy), and weight distribution. High-performance tires with sticky rubber compounds provide more grip than standard tires. Similarly, a dry, smooth road offers more traction than a wet, slippery one. Weight distribution also plays a role because the more weight on the driving wheels, the more traction you'll have.

Traction control systems use sensors to detect wheel spin and automatically reduce engine power or apply brakes to regain traction. These systems are particularly useful in slippery conditions, where it's easy to lose control due to excessive torque. They are designed to keep the vehicle moving, rather than spinning around uselessly.

Even with advanced traction control, there's a limit to how much torque you can effectively use before overwhelming the available grip. That's why it is always better to have good tires, or a vehicle with 4-wheel-drive, rather than only the highest amount of torque. It is all about keeping everything on track.

Torque Meaning, Formula, Directions & Applications AESL

Application Specificity

6. The Right Tool for the Right Job

Finally, it's crucial to consider the specific application when evaluating the importance of torque. What's ideal for one application might be completely unsuitable for another. A high-torque diesel engine might be perfect for towing a heavy trailer, but it would be overkill (and inefficient) for a small commuter car.

Think about the difference between a rock crawler and a drag racer. A rock crawler needs massive amounts of low-end torque to navigate obstacles at very low speeds. A drag racer, on the other hand, needs high-RPM power to accelerate as quickly as possible down a straight line. Different strokes for different folks, or rather, different torques for different tasks!

Similarly, electric vehicles often boast impressive torque figures, particularly at low speeds. This makes them feel very responsive and quick off the line. However, electric motors typically don't maintain high torque at high RPMs, which can limit their top-end performance compared to gasoline-powered vehicles with well-matched gear ratios. This is a challenge engineers are working hard to solve.

So, when assessing torque, always consider the intended use case. There's no one-size-fits-all answer to the question of how much torque is "enough." It depends entirely on the job at hand, and the overall design of the system.